Printmaking & Pottery R&F Encaustic Handmade Paints R&F Encaustic Paints | Sets | Mediums | Tools | R&F Encaustic Damar Resin Crystals 1Lb (454G) Bag

$28.08 $23.03

Printmaking & Pottery R&F Encaustic Handmade Paints R&F Encaustic Paints | Sets | Mediums | Tools | R&F Encaustic Damar Resin Crystals 1Lb (454G) Bag

Damar Is A Hard Natural Resin From A Family Of Deciduous Trees Growing In The East Indies. Damar Resin Is Used To Harden The Beeswax And Raise Its Melting Temperature. Damar Allows The Wax To Be Buffed To A Higher, More Translucent Surface And Helps Prevent Blooming.

Encaustic Paint Allows The Wax To Be Buffed To A Higher, More Translucent Surface And Helps Prevent Blooming In The Wax. It Is The Most Common Ingredient For Hardening Beeswax And Raising Its Melting Temperature. Using The Damar To Make Your Own Encaustic: The Medium Must Be Melted In The Beeswax And Strained. You Can Make Damar Varnish By Dissolving The Resin In Turpentine.

Note: Avoid Overheating This Product. Wax Will Release Toxic Fumes When Heated Above Decomposition Temperature. Do Not Heat Above 220 Degrees Fahrenheit. Use With Ventilation.

- Allows For A Higher Translucent Surface And Finish

- Conforms To Astm D-4236

Soy Wax (Actually Partially Hydrogenated Soybean Oil) Is An Excellent Alternative To Paraffin For Cleaning Brushes For Several Reasons. Soy Beans Are A Renewable Resource, Unlike Paraffin, Which Is A Petroleum Product. Soy Wax Is Non-Toxic And Is Naturally Biodegradable. Soy Wax Is Also Easier To Remove Than Paraffin Wax, So After The Colour Has Been Cleaned Out Of The Brush, The Brush Can Be Washed With Soap And Water And Is Reusable In Other Mediums.

Beeswax Is The Chief Component Of Our Encaustic Paint. The Beeswax Has Been Decolourized By Mechanical Filtration, Rather Than Through Bleaching Which Breaks The Wax Down. Filtering The Wax Is Gentler Process That Makes It Less Reactive To Pigments Than Chemical Bleaching. The Wax Comes Granulated So That It Is Easier To Measure And To Melt. You Can Use Beeswax As The Prime Ingredient, Along With Damar Resin, For Making Your Own Encaustic Medium. Beeswax Can Also Be Used On Its Own, But Without The Resin The Surface Will Remain Soft, As Is The Nature Of The Material.</P

Be the first to review “Printmaking & Pottery R&F Encaustic Handmade Paints R&F Encaustic Paints | Sets | Mediums | Tools | R&F Encaustic Damar Resin Crystals 1Lb (454G) Bag” Cancel reply

Related products

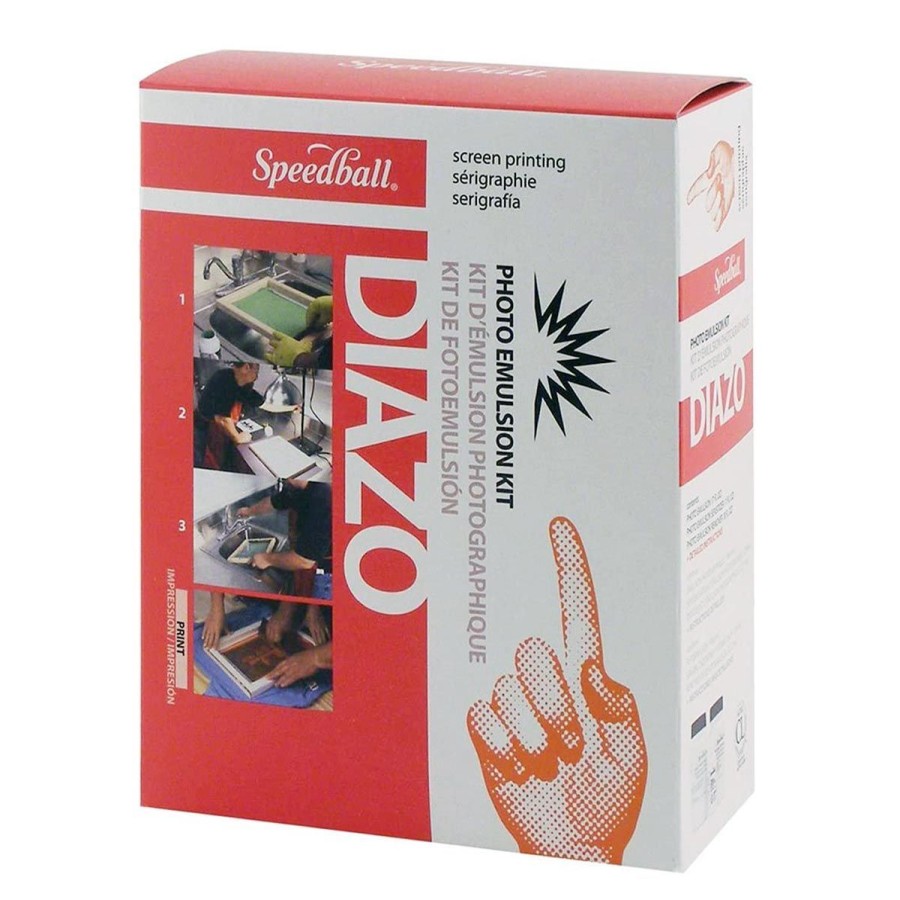

Printing Supplies | Accessories | Blocks | Stencils | Dvds

Printing Supplies | Accessories | Blocks | Stencils | Dvds

Printing Accessories Blocks | Plates | Brayers | Squeegees | Stencils

Printing Supplies | Accessories | Blocks | Stencils | Dvds

Printing Accessories Blocks | Plates | Brayers | Squeegees | Stencils

Printing Accessories Blocks | Plates | Brayers | Squeegees | Stencils

Printing Accessories Blocks | Plates | Brayers | Squeegees | Stencils

Printing Mediums

Reviews

There are no reviews yet.